Polarized Light Microscopy Digital Image Gallery

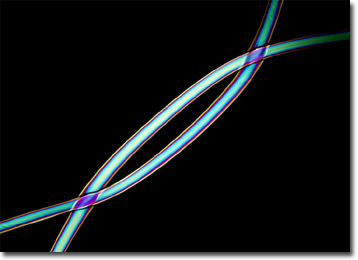

Polypropylene Fibers

Polypropylene is a thermoplastic resin that is a product of the polymerization of propylene and ethylene gases. Though it may be created in a variety of forms, only isostatic polypropylene, which was discovered in 1954, is widely utilized for commercial purposes.

Due to its many favorable characteristics and production improvements, polypropylene availability and use has increased significantly over the last few decades, a trend that is likely to continue in the upcoming years. Strong, colorfast, quick drying, stain resistant, and thermally bondable, as well as durable against chemicals, mildew, and various weather conditions, polypropylene is, indeed, well suited for a wide range of applications. Furthermore, the substance has a very low specific gravity that enables it to float when it is in fiber form. Such an array of desirable qualities make polypropylene fiber a popular component in items such as diapers, sportswear, ropes, cordage, upholstery, carpeting, and interior fabrics for automobiles. As a plastic, the substance is also molded into bottles, food containers, toys, and patio furniture.

Though highly desirable for many purposes, certain drawbacks to polypropylene use have limited its exploitation in some areas, such as the traditional textile industry. The fibers poor dyeability and texturizability, for instance, have played a significant role in the notable rarity of polypropylene in most clothing and apparel items. Other negative facets of the material are its low melting point, flammability, weak thermal stability, and poor adhesion to glues and latex. Though many of these problematic aspects may be significantly improved with the addition of other materials or by changing processing conditions, doing so is often a cost prohibitive action.