Polarized Light Microscopy Digital Image Gallery

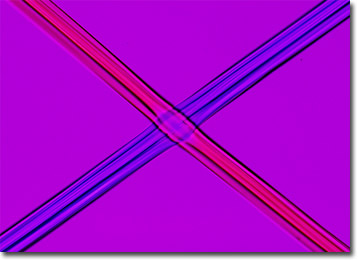

Acetate Fibers

Acetate is an important man-made cellulose-based fiber that does not wrinkle easily when worn, is somewhat stain-resistant, and is easy to care for. Yarns from the material were originally developed as an alternative to silk.

View a second image of Acetate Fibers

Acetate fiber was first produced by Camille and Henri Dreyfus, two Swiss brothers whose research efforts began in 1904 in a shack behind the house of their father. Within a year, the innovative pair had developed the first commercial cellulose acetate manufacturing process. The material was soon utilized in such products as films and toiletries, and during World War I, the brothers created acetate dope, which was used as a protective coating for airplane wings. By 1913, the pair had successfully created acetate fibers in the laboratory, but due to other concerns, the mass manufacture of the filaments did not immediately occur. It was not until 1924 that the first acetate fiber was commercially produced in the United States, where it was introduced under the trade name Celanese.

Manufactured from a renewable resource, acetate fiber is fashioned from the cellulose of softwood trees that is exposed to acetic acid and acetic anhydride before it is undergoes a partial hydrolysis to form a substance that can be easily dissolved in acetone. The solution formed by this process is passed through the small openings of a spinneret to form fibers, which are transferred into a chamber where they are exposed to warm air. The acetone readily evaporates in this environment, leaving behind the cellulose acetate fibers, which are wound on reels for later use in a wide range of products, such as ties, sweaters, lingerie, and bathing suits.