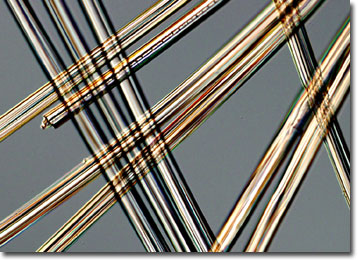

Differential Interference Contrast Image Gallery

Triacetate Fibers

Triacetate fiber was first synthesized in 1950 and began to be commercially produced in the United States a few years later. Domestic production of the material, however, ceased in 1985, though it continues to be fabricated in other parts of the world.

Derived from cellulose, triacetate is formed by combining cellulose with acetate from acetic acid and acetate anhydride. The cellulose acetate is then dissolved in a mixture of methylene chloride and methanol for spinning. Spinning, the oldest method of preparing man-made fibers, involves pumping a viscous polymer solution through a filter and subsequently passing it through the tiny holes of a spinnerette. Afterward, the solvent is removed and only a synthetic fiber remains.

Triacetate fiber is sometimes subject to static cling, but exhibits several favorable qualities. The material is shrink, stain, and wrinkle resistant, and may be machine or hand washed. It also displays excellent drapeability and provides exceptional pleat retention. Due to its no-fuss care requirements and its shape retention capabilities, triacetate fiber is frequently found in blouses, skirts, pants, and special occasion apparel, as well as draperies and upholstery.