Differential Interference Contrast Image Gallery

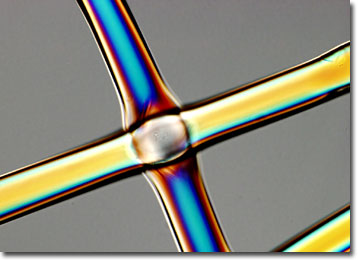

Polypropylene Fibers

A product of the polymerization of propylene and ethylene gases, polypropylene fiber was first commercially produced in the United States during the early 1960s. Since its introduction, use of the versatile material has rapidly progressed, a trend that is likely to continue in the upcoming years.

Polypropylene fiber has many positive characteristics that dictate its wide range of applications. The material is strong, quick drying, colorfast, stain resistant, thermally bondable, and hardy against chemicals, perspiration, mildew, and weather conditions. Moreover, polypropylene fiber has the lowest specific gravity of all synthetic fibers, which makes it lightweight and enables it to float in water. Due to such qualities, the material is used in an array of items, including baby diapers, hygiene products, sportswear, carpeting, upholstery, ropes, and automotive interior fabrics. Also, recently polypropylene fiber has become a common additive in concrete, believed to be an effective method of controlling shrinkage cracking.

Like most things in the world, however, polypropylene fiber is not perfect. Use of the material has certain drawbacks that have limited its use in the traditional textile industry. The most important of these shortcomings include the fiberís poor dyeability and texturizability. Low melting temperature, poor adhesion to glues and latex, flammability, and inadequate thermal stability are other negative aspects of the material. Nevertheless, many of these facets of polypropylene fiber can be overcome with the addition of other materials or by changing process conditions, though doing so can be cost prohibitive.