Michael W. Davidson

Institute of Molecular Biophysics and

Center for Materials Research and Technology,

The Florida State University,

Tallahassee, Florida 32306

Perhaps no single technology has produced such a widespread impact on science as the current revolutionary developments occurring in integrated circuit design and fabrication. Integrated circuits are now found in virtually every piece of scientific equipment on the market and new upgrades of existing circuitry are being released at an amazing rate.

The most sophisticated members of the integrated circuit family are microprocessors that serve as the central processing units of modern calculators and computers. Microprocessors have found their way into a myriad of everyday appliances such as radio, television, refrigerators, stoves, microwaves ovens, automobiles, motorcycles, electronic watches, cameras, bicycle, odometers, and home security systems. In the scientific arena, microprocessors are now found in such simple instruments as pH meters, thermometers, balances, pipettes, and even the simple light microscope.

The complex electronics involved with transmission and scanning electron microscopy led, early on, to the widespread use of microprocessors in these instruments. Only recently, however, has the microprocessor been utilized as an aid to light microscopy. Many modern light microscopes are equipped with in-camera light detection systems that feed illumination intensity information to a microprocessor that, in turn, calculates exposure times. As time goes on, the microprocessor will find increasingly more complex tasks to perform in light microscopy. Nikon has recently introduced the Microphot-FXA/L light microscope that is almost entirely controlled by a 16-bit microprocessor. Variables such as light source voltage, film speed, number of exposures, and automatic bracketing are computer controlled in the FXA/L. The user communicates with the microscope through a miniature keyboard complete with an easily discernable liquid crystal display. The microscope can even be interfaced to a printer via a parallel port on the back of the instrument or to a modem or external computer with an optional RS-232C connector. With this setup the microscopist can import a specific set of values to control any or all four of the microscope's optical ports. With the appropriate software, the microscope can be totally managed by the external computer. The expected introduction of an autofocus system coupled to an automated objective rotation nosepiece for the FXA/L should result in a microscope capable of making correctly exposed photomicrographs without direct human intervention. Even so, this is not the ultimate in computer-assisted light microscopy. Complex image analysis methods can digitize optical information for analysis with sophisticated computer systems and the recent escalation in scanning confocal microscopy research will help to permanently embed computers into light microscopy systems.

![]()

FABRICATION OF INTEGRATED CIRCUITS

Visible light microscopy plays a paramount role during the manufacturing process of integrated circuits. Wafers of pure silicon by a process that resembles dipping candles. These thin (one-tenth of a millimeter in thickness) wafers are polished and sterilized at high temperature before undergoing the complex optical lithographic process of masking, doping, and etching that can exceed 30 individual steps and take more than two months to complete. All processes are conducted in "clean rooms" that are scrupulously sterilized to remove all foreign particles and have filtered air to insure against contamination. A single contaminating dust speck during any stage of the complicated manufacturing process can ruin an integrated circuit.

Hundreds of circuits can be fabricated on a single 6-inch diameter silicon wafer. The smaller the circuit design, the more circuits can be packed onto a wafer. A single wafer, for instance, can be used to fabricate several hundred tiny binary counter circuits whereas the same wafer can only accommodate 50 or so 80286 microprocessors that are about 1 cm2. Circuit testing is conducted throughout the manufacturing process. Wafers are examined with reflected light microscopes for analysis of gross morphological features and various portions of the wafer are probed with detectors to determine overall circuit integrity. Often, test circuits are fabricated directly on the wafer to aid in component examination. Typically as many as 70% of the circuits on a particular wafer become defective before completion of the manufacturing process.

![]()

PHOTOMICROGRAPHY OF INTEGRATED CIRCUITS

One need not be employed by the semiconductor industry to be able to photograph integrated circuits through the microscope. Complete wafers are difficult to obtain, however discarded computer parts are an excellent source of integrated circuits. These silicon "chips" are cut from wafers with a diamond-tipped saw and are generally packaged by either molding into an epoxy resin case or cemented into a ceramic case. It is virtually impossible to recover an integrated circuit from an epoxy resin case. During the manufacturing process, the resin flows onto the surface of the chip and penetrates into the etched microstructure. When the epoxy cases are broken or cracked open, the silicon fractures through the center of the integrated circuit and all surface detail is lost. The cement in a ceramic case can, however, be scored with a hacksaw and split with a fine chisel to reveal the internal chip. Most programmable read-only memory (PROM), microprocessors, math coprocessors, and some random access memory (RAM) integrated circuits are protected with ceramic cases. In addition, many analog and binary circuits that perform simple functions are packaged in ceramic cases. In addition, many analog and binary circuits that perform simple functions are packaged in ceramic cases. To identify an integrated circuit, take note of the markings on the case before opening. These markings usually consist of a manufacture date, the manufacture, and a symbol or number code that identifies the circuit. In most instances, this information is also etched onto the surface of the chip itself and can be revealed by examination with a reflected light microscope.

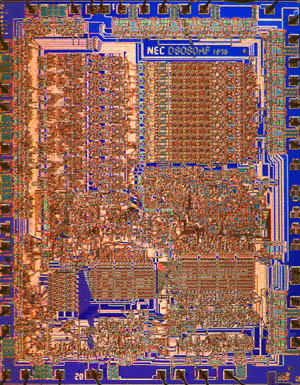

Examination of integrated circuits with reflected light can serve many purposes. For instance, details of a particular circuit structure such as register areas, data busses, memory storage, logic units, and even individual transistors can be identified and examined. By observing differences in the architecture of various integrated circuits, one can begin to get a handle on the complex electronics involved in modern devices. The figure illustrates a Nippon Electric Company (NEC) copy of the famous Intel 8080 microprocessor introduced in 1974 as the first stand-alone microprocessor. The introduction of this revolutionary microprocessor was a key factor in the early growth of a fledgling personal computer industry and it's application in the MITS Altair 8800 computer was introduced on the July 1975 cover of Popular Electronics.

Reflected light microscopy is the method of choice for examining integrated circuits. Circuits can be visualized using brightfield, darkfield, and differential interference contrast, and fluorescence microscopy. Usually, more detail is apparent when the microscope is operated in the differential interference contrast (DIC) mode. By inserting a retardation plate between the polarizer and sample, a color spectrum is generated in DIC that allows for a greater differentiation of the various details on the surface of integrated circuits. This method also produces the most colorful photomicrographs.

A stereo microscope also can be very useful in the examination of surface detail on integrated circuits. This is especially true of the larger microprocessors that exceed 1 cm2 in area. By adding color filtration to the light sources for stereo reflected light microscopy, one may acquire colored highlighting effects that enhance the appearance of integrated circuits in photomicrographs. It is interesting to experiment with several light sources each with a different color filter. Quite a number of special highlighting effects can be obtained this manner.

![]()

HISTORY AND FUTURE OF THE MICROPROCESSOR

As I have described above, the microprocessor has had a major impact on science and industry and touches the lives of almost every individual in developed nations. The most prominent microprocessors in use are probably the 8000 series first introduced by Intel in 1972. The development of microprocessors has been a blend of increasing bus width and register size coupled to a steady reduction in component size. The apparent limit is dictated by the minimum allowable channel length of the metal-oxide-silicon field-effect transistor (MOSFET) and also limitations on transistor packing efficiency. As components grow smaller and more tightly packed, total overall chip size increases to accommodate larger registers and additional busses. Intel has speculated that by the year 2000 they will have developed a microprocessor with 100 million transistors, operating at 250 MHz with an execution rate of 2000 million instructions per second (MIPS). This superchip is expected to operate 80 times faster than the current highest-speed i486.

|

|

The following list contains a short description of the most prominent members of the Intel 8000 microprocessor series.

8008. This was the first microprocessor with an 8-bit data bus. It was an update of the original 4004, Intel's first microprocessor developed in 1971 for a Japanese calculator firm. The 8008 was useful in the earliest attempts at building personal computers.

8080. This was the first 8-bit microprocessor designed for general use as a stand-alone central processing unit (see the figure on page 5). It was introduced in 1974 and contains 4,500 transistors. At an execution rate of less than 1 MIPS, this microprocessor found a limited use in the development of personal computers.

8086. Introduced in 1978, this 16-bit microprocessor was too advanced for the industry standard 8-bit technology of the day. It's 20-bit address bus allowed the chip to address 1 megabyte of memory in contrast to the 64-kilobyte limit of the 8080.

8087. A backward step in technology, this chip was introduced in 1979 to compete as the processor for the emerging IBM line of personal computers. Like the 8086, the 8088 execute commands internally with a 16-bit data bus, however it communicates with peripherals with an 8-bit external data bus. This microprocessor, which operates at a clock frequency of 4.77 MHz, became the brains behind the IBM PC and XT series of personal computers.

80286. This 16-bit microprocessor first appeared in the IBM AT series of personal computers. It features increased speed over it's predecessors and added a new feature called protected mode, which allows advanced memory management techniques. The increased address bus size allows this chip to address 16 megabytes of memory. Initial clock frequencies were 8 MHz, with later versions featuring increased frequencies of 12 and 16 MHz.

80386. First offered as the microprocessor controlling the Compaq 386 in 1985, this 32-bit chip can address 4 gigabytes of physical memory and up to 16 terabytes of virtual memory. This amazing microprocessor is also capable of operating in a virtual 8086 mode that allows the microprocessor to simulate an almost unlimited number of 8086 processors running independently, but simultaneously. The original version operated at 16 MHz., but later versions are capable of operating at clock speeds as high as 33 MHz. This microprocessor maintains downward compatibility with previous Intel microprocessors so that a program written for an 8088, for example, can easily be executed with the 80386.

80386SX. Like the 8088, this microprocessor was a backward step introduced by Intel in 1988 as a low-cost alternative to the 80386. In a sense, this microprocessor is related to the 80386 in the same manner as the 8088 are to the 8086 with a reduced external data bus size. The 80386SX execute 32-bit commands internally but communicate with external devices through a 16-bit bus. This allows the 80386SX to take advantage of cheaper 16-bit AT hardware while maintaining compatibility and the memory management capabilities of its more advanced cousin.

80486. Intel's latest addition to the 8000 series is the 80486-also called the i486-introduced in 1989. This microprocessor is essentially an 80386 with several support peripherals built on-board. The chip contains, in addition to a complete 80386 microprocessor, an 80387-math coprocessor and an 8K random-access memory cache for almost explosive speed.

80586 & 80686. The 80586 are currently under development by Intel while the 80686 are still on the drawing board. Except the release of these chips within the next several years.

As the microprocessor signals an "information revolution" in science and society, one is left only with speculation as to the limits of integrated circuit technology. However, it is for certain that microscopy and advanced computer systems will walk, hand-in-hand, into the future.

![]()

ACKNOWLEDGEMENTS

The author would like to thank the FSU Center for Material Research and Technology (MARTECH) for financial support and the Nikon Instrument Group for providing equipment and technical support.