How a Digital Video Drive Works

During the later months of 1994 and the early months of 1995, four companies began production of the standards that eventually led to the design of the digital video disk (DVD). Initially led by Phillips and Sony, a singled sided, dual layered high-density disk was developed. Then Time-Warner and Toshiba followed suit, creating a double-sided disk. For nearly a year, these competing manufacturing groups tried to prove the technological superiority of their products, which in time led to the established standards of the DVD. Along with that history, there is a complicated process for creating a digital video disk.

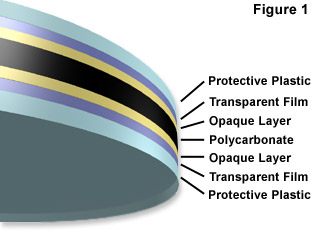

The process of creating a finished DVD product begins with the construction of the disc, which consists of four main layers (Figure 1). The first layer is made up of a thick polycarbonate plastic, like that of a compact disc. Above that is a thin layer of opaque, reflective material, followed by a transparent layer of thin film. Finally, a protective layer of plastic is added to the foundation. And also like a compact disc, the data is transferred onto a DVD through the use of stripes (or pits) and lands. The combination of these rivets and flat surfaces on not one, but two separate surfaces is what separates the DVD from a compact disc in terms of data capacity.

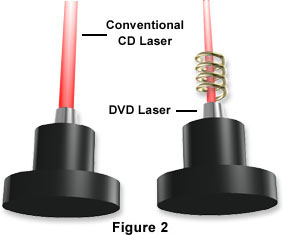

Similar to a CD-ROM drive, a DVD drive uses a light beam (laser) to read the stripes and lands on the surface of a disc. But unlike the CD-ROM, the DVD drive uses a relatively smaller beam of light to read the information put on the disc surface. This permits a greater amount of stripes and lands to be held on the two surfaces of the digital video disk, which leads to a thirteen-fold increase in the capacity of a normal compact disc. Also, the read head on the DVD drive is equipped with a magnetic coil that allows it to change the flow of current through the laser, enabling the focus of the light beam so that it may be concentrated on either of the two surface layers (Figure 2).

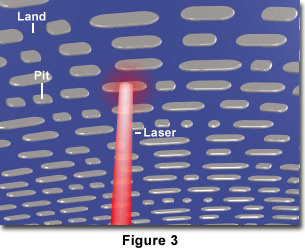

Another similarity between DVD and CD technology is the way stripes and lands on the surface of the discs are read. By focusing a laser beam from the read head on to the surface of the disc, the light can either reflect back or scatter, as shown in Figure 3. When the laser beam comes in contact with a land, the reflective material sends the light back into the head, triggering an electric impulse. Alternatively, when the light beam comes in contact with a stripe, it is scattered off in all directions. These electric impulses are then converted into 0s and 1s by the drive, and sent in as a string of binary or digital data to the software controlling the device.

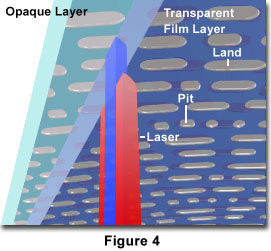

What sets the DVD drive apart in terms of storage space, however, is that it has two separate surfaces for writing stripes and lands. As shown in Figure 4, the transparent surface that is near the top, is one of the writing layers, and the opaque layer below that is the other. By being able to focus the concentrated light beam on either one of these layers, the capacity of a normal, single-layered disc is essentially doubled. This, in combination with the fact that DVDs have a more tightly wound spiral, and accordingly, a smaller laser to read them, is the reason a digital video disk has immensely more storage space than a typical compact disc. This capacity is furthered doubled in today's technology, because digital video disks now have both a transparent and opaque layer on each side of the disc.

BACK TO ELECTRICITY AND MAGNETISM HOME