How a Writable CD Works

Compact disc technology came into the mainstream during the mid 1980's when audio compact discs (CDs) started to become popular. Soon after, compact discs began to be used to store computer programs. This sudden rise in acceptance can be mainly attributed to a set of standards developed by Sony and Phillips, called the "Color Books." They outlined the specifications that all CD technology would follow for years to come, and allowed a template for the development of compact discs and related technological advances.

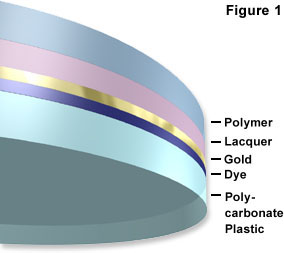

While the history of compact disc technology is easily attainable, lesser known is how the CDs are actually written or "burned". The basic standard supported by all CD-ROM drives to read compact discs is used when data is transferred onto them. A write head located in a writable CD drive completes the process. The write head sends a laser (low-energy light) beam to the surface of a compact disc built primarily with a thick layer of clear polycarbonate plastic (Figure 1). Located above the layer of plastic, are a dyed (usually green) layer of material and a thin layer of gold that reflects the light beam. Above that is a protective layer of lacquer, followed by a scratch-resistant layer of polymer material.

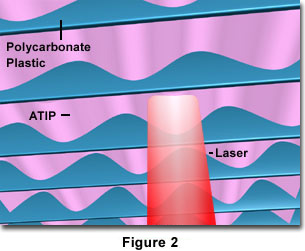

The laser projected by the write head follows a tight spiral groove that has been cut into the plastic layer. This groove is known as an atip, and stands for absolute timing in pregroove. It has a continuous wave pattern etched into it, similar to that of a record player, as illustrated by Figure 2. The light beam follows this wave pattern from the beginning of the compact disc to the end, maintaining a continually varying frequency. By reading the frequency of the wave pattern on the compact disc, the write head is able to determine its location in relation to the surface.

While the write head is following the groove in the surface, a motor is controlling the speed at which the compact disc rotates. This speed is determined by the position information that the write head is receiving from the wave patterns. This is used to keep the area that is in direct contact with the light beam at a constant speed. In order to make this possible, the motor must make the disc turn faster at the write head reaches the center of the disc, and slower as it nears the outer rim.

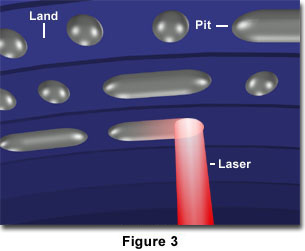

Software used to control the writing of data to the compact disc depends on specific formats such as ISO 9096 or JOLIET to correct any errors and create a table of contents. Unlike a hard drive's file allocation system, a compact disc drive has no way of keeping track of the locations of files on the surface of the disc, thus a table of contents is necessary. This information is recorded on the CD with a powerful pulse of light that projects a laser beam at a wavelength of 780 nanometers. Absorbing light at precisely that wavelength, the color dyed layer is marked on by the laser beam in one of three ways depending on how the compact disc is designed. The creation of these marks on the disc surface is illustrated in Figure 3.

Regardless of how the disc was designed, the distortion created on the surface is known as a stripe (or a pit). The lengths of the stripes vary depending on what information is being written to the disc. The write head uses these different lengths of stripes to write the information in a way that compresses the data and checks for errors. These distortions created in the color dyed layer are permanent, making the disc into a read-only medium.

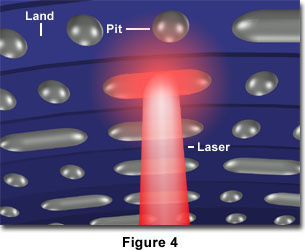

Any CD drive, regardless of its capability to write to the surface of a disc, has a read head. This read head, unlike the write head, uses a lower powered beam of light that is projected on the surface of the CD to merely read data. When the beam is following the grooves in the surface, it comes across the distortions created earlier. When it hits a stripe, the light is scattered and does not return to the read head (Figure 4).

However, when the light hits a surface with no distortions (a land), the laser is reflected back into the beam head, triggering an electronic impulse. The pattern of these electronic impulses is decoded by the CD drive, and is sent to the computer as a binary or digital data stream in the form of 1's and 0's. These strings of data are then interpreted by the computer from anything ranging from an executable program, to a full motion video, to an audio clip.

BACK TO ELECTRICITY AND MAGNETISM HOME